Currently, every company needs to remain its own characteristics to keep pace with the innovation of the times in the competitive market. Therefore, selecting the best and most appropriate systems is of great importance. Automated storage systems, such as the AS/RS system, the Shuttle- Stacker crane system and the Four-way Shuttle system will definitely not only bring the warehouses of each company much more advanced storage solutions, but also long-term benefits. Probably a little bit more costs will be paid in the short run, but the economic savings in the long run are immeasurable. For instance, for a fully automated storage system in a freezer, there is no need to purchase forklifts or to leave the door of the freezer open every day. Thus, cost on air conditioning can be minimized.

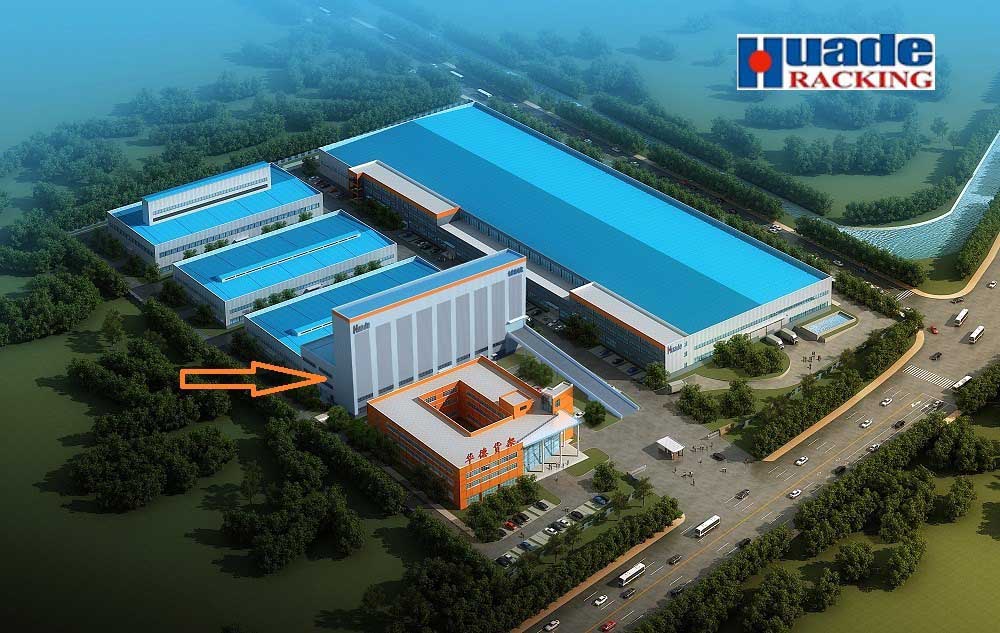

In order to demonstrate, test and meet the growing requirements of warehouse storage , HUADE invested more or less US$3 million to build the 40 meter high lab of 3800 square meter area, , it is a rack clad warehouse supported by the automated storage system.

Owing to the previous experience of the completion of the 40 meter high AS/RS in Nanjing in year 2015, HUADE understands how to build the lab well. The intention is to continuously make improvement on our automated storage systems, also for better demonstration and full use of the warehouses in the factory.

This year HUADE is building 4 rack clad automated warehouse simultaneously, one with shuttle-carrier system in Beijing, one with ASRS in Bangladesh, one with ASRS in Chile, and this last one in HUADE’s own factory will be equipped with ASRS and 4-way shuttle system.

We believe the storage systems designed, manufactured by HUADE through countless tests in the lab will bring new experience to warehouse operation, along with more benefits and lower maintenance.

Post time: Nov-26-2020