China Wholesale Fruit Cold Storage System Factories – Shuttle Racking System – Huade

Short Description:

China Wholesale Fruit Cold Storage System Factories – Shuttle Racking System – Huade Detail:

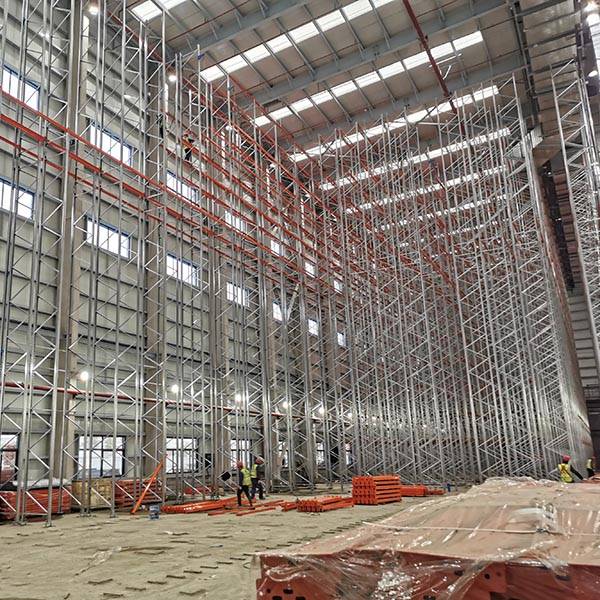

The shuttle racking system is a high-density storage system that uses shuttles to automatically carry loaded pallets on the rail tracks in the rack. The radio shuttles are remotely controlled by an operator. There is an optimum use of storage space, and workplace safety is well maintained because the forklift doesn’t need to be driven in the racks or aisles between racks, therefore, maintenance costs are reduced for the sake of less damage of the racks.

The shuttle racking system can work either as First in, First out (FIFO) or as Last in, First out (LIFO), for large quantities of same products like beverage, meat, sea food, etc. it is an ideal solution in cold storage with temperatures of down to -30°C, because the space utilization is vital to cold storage investment.

It is also possible to control the inventory through a system of sensors which count the stored pallets, and the gap between pallets are adjustable for compacting the storage space or ventilating the cold air better.

1.Cost effective and time-saving; forklifts are not required to enter the racking area, shuttles can work continuously while operator handles the pallet with forklift

2.Low level of risks or damage to the racks and operating staff

3.Maximum floor space utilization, the aisle for forklift in selective racks is eliminated, space utilization increased almost 100%.

4.Automatically handles pallet picking and retrieval with high precision

5.Operating temperature 0°C to +45°C / -1°C to -30°C

6.Available in different pallet configuration scenario FIFO/LIFO, of course it requires planning of the racking configuration

7.The pallet configuration can go up to 40m deep in the lane

8.Up to 1500 kg/pallet could be handled in the system

9.Scalable solution which means more shuttle could be put into the system to increase efficiency

10.Built in safety feature like pallet guide centralizers, rail end stoppers, photoelectric sensors, etc.

Product detail pictures:

Related Product Guide:

Our primary target will be to provide our clients a serious and responsible small business relationship, supplying personalized attention to all of them for China Wholesale Fruit Cold Storage System Factories – Shuttle Racking System – Huade, The product will supply to all over the world, such as: Austria, Italy, Sacramento, Our company follows laws and international practice. We promise to be responsible for friends, customers and all partners. We would like to establish a long-term relationship and friendship with every customer from all over the world on the basis of mutual benefits. We warmly welcome all old and new customers to visit our company to negotiate business.

Reasonable price, good attitude of consultation, finally we achieve a win-win situation,a happy cooperation!