China Wholesale Automated Warehouse Factory – Shuttle Stacker_crane – Huade

Short Description:

China Wholesale Automated Warehouse Factory – Shuttle Stacker_crane – Huade Detail:

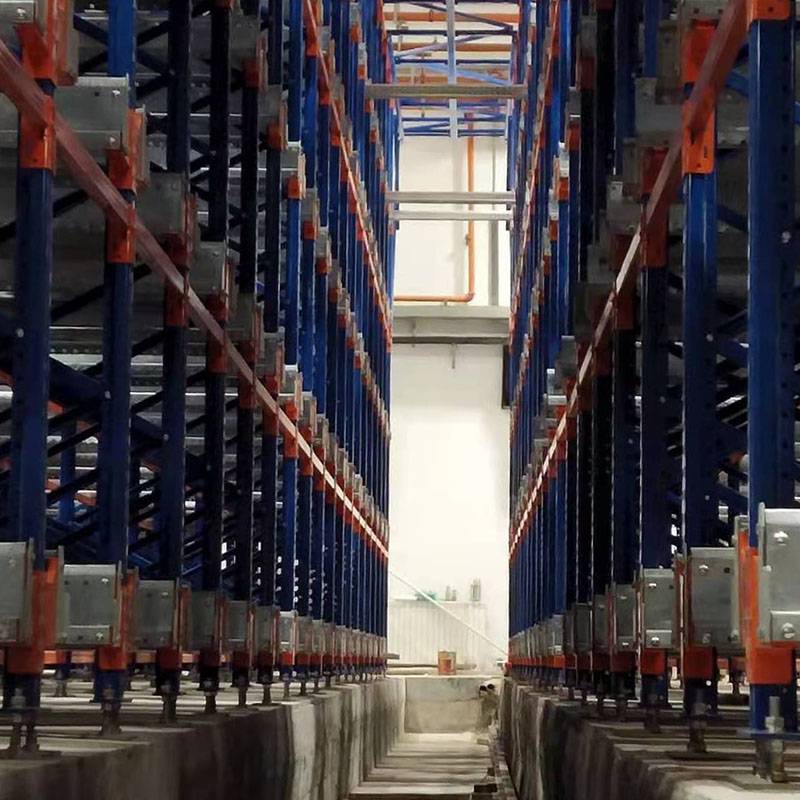

The Stacker crane access to pallets in the shuttle racking lanes on both sides. This solution reduces the total cost while providing high density storage, and fully utilizes the floor space and vertical space. The storage lanes are fitted with rail tracks on which shuttles can run. Shuttle and stacker crane therefore form one logistical unit: the shuttle runs on the rails to an allotted storage position where it sets down or picks up a pallet, and the stacker crane transports the shuttle to the storage lane in the racks.

Pallet shuttle + Stacker Crane AS/RS solutions provide maximum storage density with deep storage lanes and also reduces the need for forklifts to store and retrieve pallets. By using a cart system to transport pallets into the buffer, forklifts no longer need to travel beyond the shipping dock and lane entry. Shuttles can move pallets in and out of storage lane as well as the benefit of stacker crane to move pallets horizontally and vertically through any level of storage. Shuttle and stacker crane combination provides an automated solution that innovates traditional storage and retrieval operations with speed and accuracy, also cuts the labor cost in the long run.

Minimal downtime

Low- maintenance

Higher density storage being compared with AS/RS

Fully vertical space utilization

Flexible selectivity in different lanes while FIFO in a certain lane

Flexible layout configuration for various load sizes and weights

With WMS/WCS, the operation and inventory management can be automatic

Low labor cost in the long run

Rack clad warehouse building can be an option to further save the construction cost

HUADE has accumulated much experience and many cases with shuttle and stacker crane automated system, such system saves cost and increase the storage density by increasing the depth of pallets in the lane, for storage without high demand of inbound and outbound efficiency, it is a perfect solution regarding cost and storage density.

Product detail pictures:

Related Product Guide:

To regularly increase the management program by virtue from the rule of "sincerely, good religion and high quality are the base of enterprise development", we greatly absorb the essence of linked products internationally, and constantly produce new goods to satisfy the calls for of shoppers for China Wholesale Automated Warehouse Factory – Shuttle Stacker_crane – Huade, The product will supply to all over the world, such as: Senegal, Melbourne, Guatemala, we rely on own advantages to build a mutual-benefit commerce mechanism with our cooperative partners. As a result, now we have gained a global sales network reaching the Middle East, Turkey, Malaysia and Vietnamese.

We are really happy to find such a manufacturer that ensuring product quality at the same time the price is very cheap.