Best High Quality Mold Racking Suppliers – Push Back Rack – Huade

Short Description:

Best High Quality Mold Racking Suppliers – Push Back Rack – Huade Detail:

The right storage system can increase the storage space and save a lot of working time, Push back rack is such a system that maximizes storage space by reducing aisles for forklifts and saving operators’ time running in the racking lane like what happens in drive-in racks.

Each pallet is loaded in sequence onto wheeled carts at differing heights, and is then pushed further back into the lane by subsequent deposits. Inclined steel guide channels make sure the pallets are kept in place to fully utilize the depth of each aisle.

A pushing force is used to place a new pallet, where the forklift pushes the unit loads already stored towards the back, making space for the new pallet to be deposited, hence the term “push-back”.

Pushback racking is ideal when identical palletized goods are put in the warehouse. Unlike drive-through racking, goods are stored and retrieved from one side . This reduces transport routes and also saves working time. Pushback racking consists of racking uprights connected together to form an aisle. The rails cross the beams are tilted for easy retrieval of pallet, with the following pallet moving up automatically. Stacking is typically done lengthways by forklift trucks, units already stacked must be pushed up along the tilted rails.

Push back racking system is a system especially designed for LIFO stocking scenario (Last in, First out), where the last pallet placed on is the first to be retrieved. Unlike FIFO stocking, which needs one side of the aisle for loading and another side for unloading, in push-back racking, the forklift accesses the stored pallets along a single work aisle.

Optimum use of space with dynamic block storage

Flexible expansion

Saving time since the forklift moves less

Shorter internal transport distances

Floor space utilization optimized

Very little vertical space is wasted

Each level can store a different SKU

Till to now we have exported push back racks to many countries such as Sri Lanka ,Ukraine ,Poland, France ,England, Philippines UAE and so on

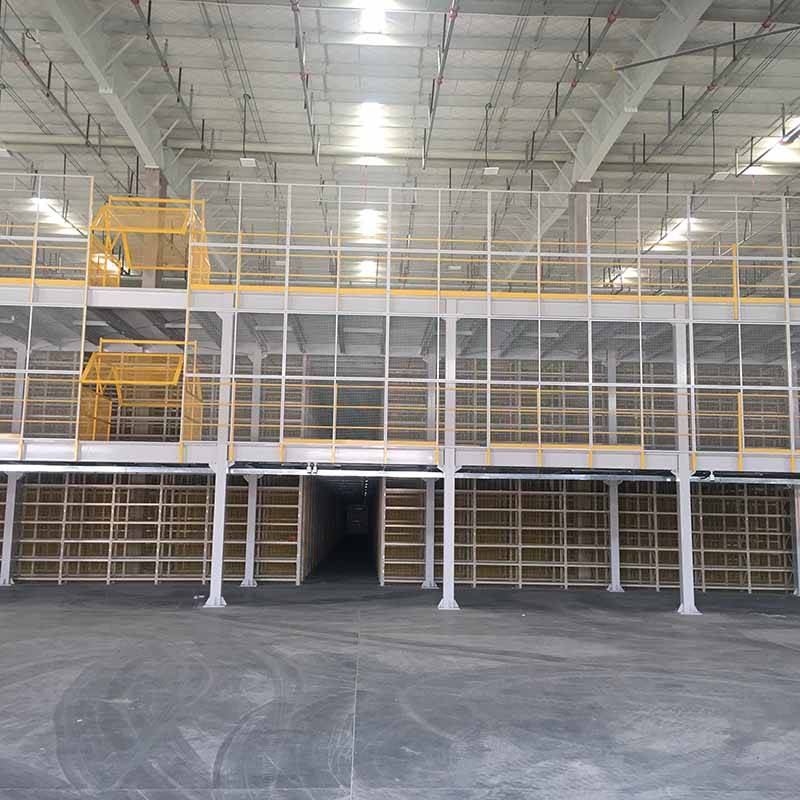

Product detail pictures:

Related Product Guide:

We can easily normally satisfy our respected buyers with our excellent high-quality, excellent selling price and good service due to we've been far more expert and more hard-working and do it in cost-effective way for Best High Quality Mold Racking Suppliers – Push Back Rack – Huade, The product will supply to all over the world, such as: Ireland, Sri Lanka, Argentina, With more and more Chinese products and solutions around the world, our international business is developing rapidly and economic indicators big increase year by year. We have enough confidence to supply you both better solutions and service, because we've been more and more powerful, specialist and experience in domestic and international.

In our cooperated wholesalers, this company has the best quality and reasonable price, they are our first choice.