Best High Quality Automated Warehouse Factory – 4-Way Shuttle – Huade

Short Description:

Best High Quality Automated Warehouse Factory – 4-Way Shuttle – Huade Detail:

4-Way shuttle is an automated handling equipment for high-density storage system. Through the 4-way movement of the shuttle and the level transfer of the shuttle by the hoist, the warehouse automation is achieved. This smart material handling equipment can travel in 4 directions working efficiently and flexibly across multiple lanes and making full use of space with less restriction. The shuttle connects to the RCS system via wireless network, and travels to any pallet location working with the hoist.

The four-way shuttle is equipped with an independent PLC to control the walking, steering, and lifting.

The positioning system transmits the key coordinate position of the four-way shuttle to the PLC.

Information such as battery power and charging status is also sent to the PLC.

The local operation of the four-way shuttle is realized through a handheld terminal via wireless communication.

When an alarm occurs, the four-way shuttle is switched to manual mode and stopped normally. Emergency stop is used only when the shuttle position exceeds the limit, or there is collision, or emergency stop alarm occurs.

a. The four-way shuttle has the following safety functions:

Rail boundary collision protection

Anti-collision protection for obstacles in the rail track

Anti-collision protection for obstacles in the racks

Overcurrent protection for motor

Protection of battery short circuit / over current / under voltage / over voltage / high temperature

b.The four-way shuttle has the following detecting functions:

Pallet detection when picking up

Empty pallet location detection before storing pallet

Load detection on the shuttle

Robot path planning and robot traffic management allow the robot clusters to work together in coordination, to cooperate with each other without affecting each other and consequently maximize the performance. RCS is also responsible for monitoring the operating status of the robots, recording the status of each robot, and further determining whether the maintenance for specific robot is required. Considering the operating status of the charging station and the current task execution, RCS arranges necessary charging direction for robots in need of power, records, summarizes and analyses all the alarm information coming from the robots, then notifies the maintenance personnel, advises diagnosing and repairing methods, and further ensures the reliability of the entire system.

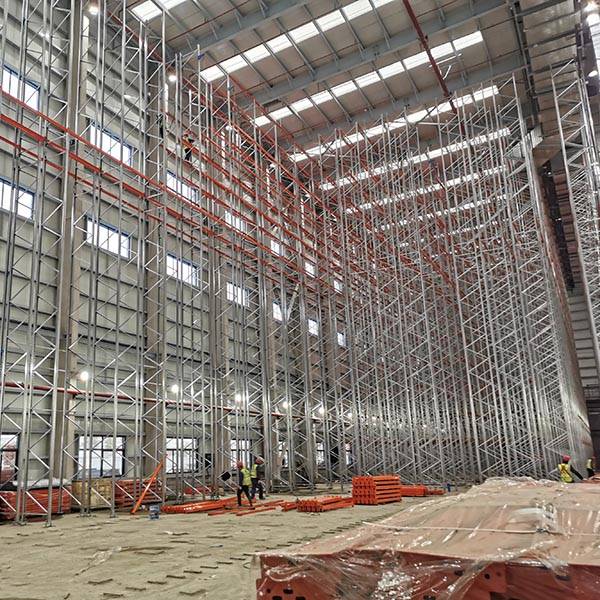

Product detail pictures:

Related Product Guide:

continue on to further improve, to make sure product top quality in line with market and consumer standard requirements. Our firm has a excellent assurance program have already been established for Best High Quality Automated Warehouse Factory – 4-Way Shuttle – Huade, The product will supply to all over the world, such as: Cyprus, Botswana, Cyprus, Now we've been sincerely consider to grant brand agent in different areas and our agents' maximum margin of profit is the most important thing we care about. Welcome all of the friends and customers to join us. We have been ready to share win-win corporation.

The company comply with the contract strict, a very reputable manufacturers, worthy a long-term cooperation.